| Availability: | |

|---|---|

| Quantity: | |

KLG-600SA

KLG-600SA 99% Pure Copper Wire Granulator Separtor Machine is professional line for recycling waste wires /cables. With a pre shredder in the production line, make an impressive production capacity and wide application for different size cables. The shredder can process other material not only cables, such as automobile wires, car bottom wires, motorcycle wires, computer wires and communication cable, waste radiators, steel sheets etc.

After pre shredding, it will do grinding and separating the pvc and copper. Work with dry type air separating device. With KLG-600SA 99% Pure Copper Wire Granulator Separtor Machine, you can recycle the waste copper wire and cables into clean tiny copper and plastic granulations.

If vibrating tables and electrostatic separator equipped in the line, the purity can reach 99.9%. The selling price of copper granulates will be much higher than usual.

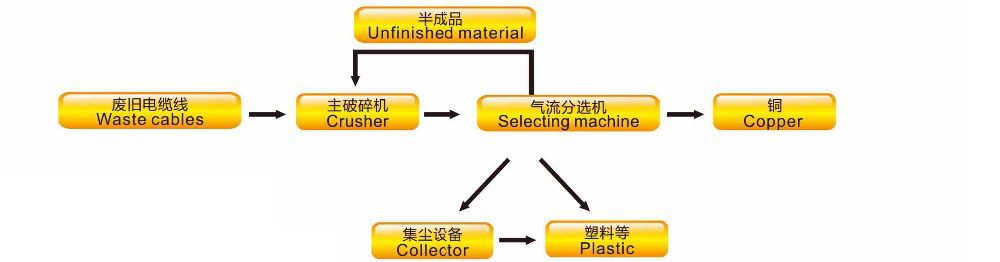

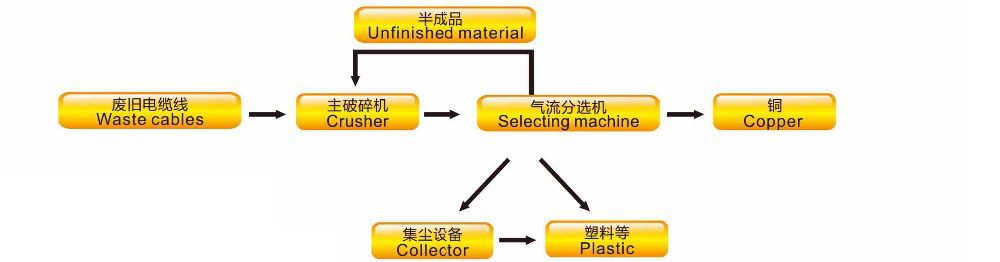

Pre-Shredding→ Crushing→Air separating→Dust collecting→Iron removal (optional)→Secondary Separating (Optional)

1. Compact structure, reasonable layout, easy installation and transportation.

2. PLC control to ensure the evenly feeding, efficient running without stuck.

3. Special designed crusher makes less noise but bigger output, alloy steel tool blades used.

4. Vibrating table for secondary separation, much high purity reaches 99.9%

5. Dust collection device for creating clean operating space.

6. Big capacity double shaft shredder to ensure capacity, amazing processing capacity.

Model: KLG-600SA 99% Pure Copper Wire Granulator Separtor Machine | |

Cable input limitation | 0.15-30mm |

Output | 400-800kg/hour |

Total power | 64kw |

Machine weight | Around 5500kg |

Overall size | 1000cm*450cm*250cm |

| Voltage | 380V/50Hz (Customized) |

| Shipping | 1*40" container |

Lifelong Maintenance and considerate technical support.

Any problem before or after, you could find and talk with us anytime anywhere.

Technicians can be sent to abroad, door to door service.

Vedio/CD of test running and installation, Users' Manual provided.

Complete parts & tools in box sent with machine.

We can study the projects with customers together to help them to make best investment with less cost.

KLG-600SA 99% Pure Copper Wire Granulator Separtor Machine is professional line for recycling waste wires /cables. With a pre shredder in the production line, make an impressive production capacity and wide application for different size cables. The shredder can process other material not only cables, such as automobile wires, car bottom wires, motorcycle wires, computer wires and communication cable, waste radiators, steel sheets etc.

After pre shredding, it will do grinding and separating the pvc and copper. Work with dry type air separating device. With KLG-600SA 99% Pure Copper Wire Granulator Separtor Machine, you can recycle the waste copper wire and cables into clean tiny copper and plastic granulations.

If vibrating tables and electrostatic separator equipped in the line, the purity can reach 99.9%. The selling price of copper granulates will be much higher than usual.

Pre-Shredding→ Crushing→Air separating→Dust collecting→Iron removal (optional)→Secondary Separating (Optional)

1. Compact structure, reasonable layout, easy installation and transportation.

2. PLC control to ensure the evenly feeding, efficient running without stuck.

3. Special designed crusher makes less noise but bigger output, alloy steel tool blades used.

4. Vibrating table for secondary separation, much high purity reaches 99.9%

5. Dust collection device for creating clean operating space.

6. Big capacity double shaft shredder to ensure capacity, amazing processing capacity.

Model: KLG-600SA 99% Pure Copper Wire Granulator Separtor Machine | |

Cable input limitation | 0.15-30mm |

Output | 400-800kg/hour |

Total power | 64kw |

Machine weight | Around 5500kg |

Overall size | 1000cm*450cm*250cm |

| Voltage | 380V/50Hz (Customized) |

| Shipping | 1*40" container |

Lifelong Maintenance and considerate technical support.

Any problem before or after, you could find and talk with us anytime anywhere.

Technicians can be sent to abroad, door to door service.

Vedio/CD of test running and installation, Users' Manual provided.

Complete parts & tools in box sent with machine.

We can study the projects with customers together to help them to make best investment with less cost.