Views: 13 Author: Site Editor Publish Time: 2021-10-09 Origin: Site

Our client from Argentina is well reputed enterprise who focus on electric waste recycling. He had a good study on wire granulator machines by comparing the European, American also Chinese machines.

Finally, it took nearly one month for him making decision on KLAY granulator. Our engineers also joined in technical discussion to give the rightest proposal.

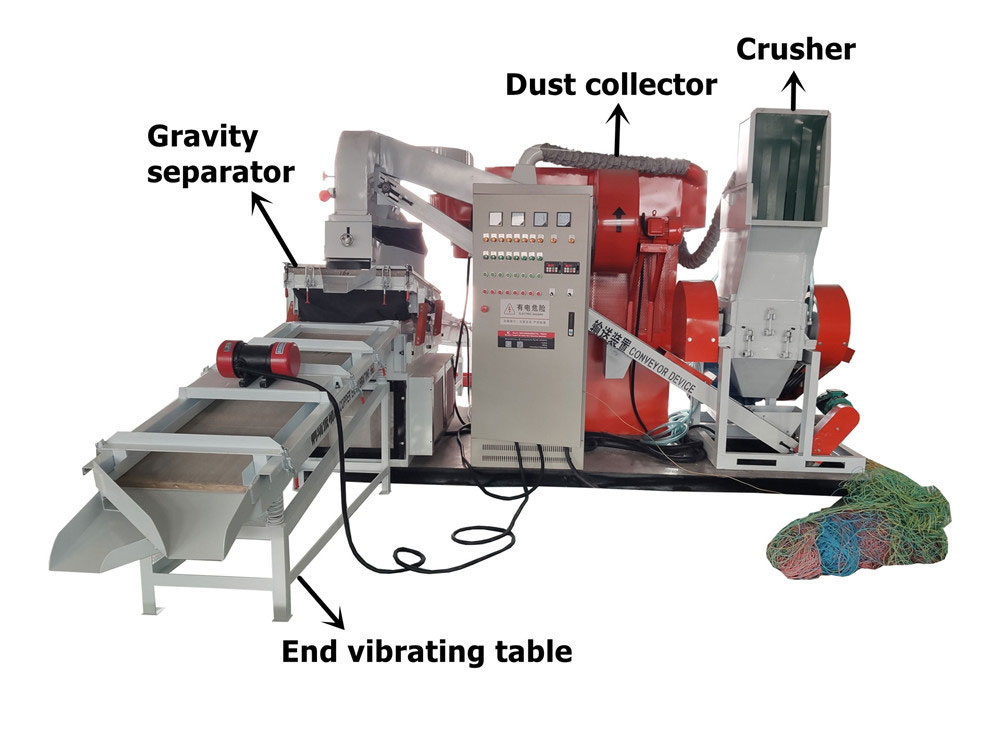

Usually the smallest size of our new generation cable granulator is KLG-600S (production capacity 350~500kg/hour). But client only required 200kg/hour production, so engineer team suggested to use a little smaller crusher (else keep the same with 600S), then KLG-400S came out.It is customized small size granulator (production capacity 200~250kg/hour) but with newest design and best performance (separation rate up to 99.9%).

The total volume of KLG-400S small cable granulator is over 20CBM, weight around 3000kgs. As you see, it requires one 20feet container for shipping. But the freight rates raised nearly 3-4times than last year, we have to find another way to load the cable granulator. After well discussion with client, we decide to do wooden packing for whole machine, and load by LCL in one 40feet container.

By this way, we saved nearly 10,000usd for client. And the machines arrived safely after 40days.

Before the machine's arrival, we provided the machine Manual and layout drawings for our client doing site preparation. Also guided him the electricity preparation. Once he placed the machine well, we kept online talking with him about commissioning or video calls until the machine runs stably.

During the future running of our wire granulator machine, we do regular inspection with clients' feedback. The Maintenance Manual or Tips must be provided to each our client as well.

Some times, clients has different production requests (mainly bcs they changed the material), we should give him right instructions on operation or parts adjustment. Surely, all machine parts will be supplied in competitive factory prices.